Developing an AI-powered, risk-based pipeline integrity management system.

dashboard Objectives

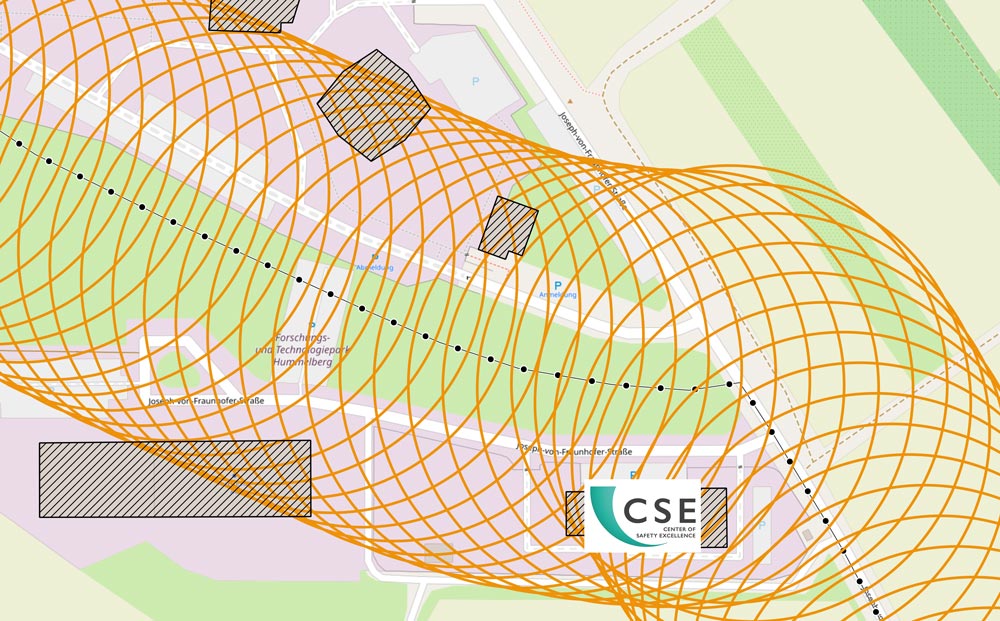

The aim of the RiIM project is to develop a new integrity management method to extend the condition assessment of high-pressure gas pipelines with AI systems and to perform risk-based prognoses on the technical safety of pipeline sections. For this purpose, an extended Risk-based Integrity Management (RiIM) module will be developed, tested and validated on the basis of existing PIMS approaches.

The RiIM module is intended to go beyond the current practice of maintenance and servicing forecasts to also assess the technical safety of gas pipelines, as far as this is possible with the available data. New challenges for forecasting such as hydrogen feeds or natural hazards due to climate change (NaTech – events) are to be included in the analysis.

With RiIM, the concept of “H2 readyness” is also extended to the PIMS. Not only the hardware must be adapted, but also the integrity management!

dashboard MILESTONES

Summary of the state of knowledge

Risk assessment

Integrity modeling

RiIM application and validation

Comparison with classic PIMS systems

dashboard Overview

New Integrity Management Method for improved Integrity Evaluation

Broader data basis through AI support

Risk-based forecasts for technical safety

Consideration of NaTech events and H2 injection

dashboard Motivation

According to the Energy Economy Act, gas networks must be operated safely. Hazards to people and the environment must be reasonably excluded. Integrity Management Systems (IMS) are used for the safe operation of gas networks. Based on pipeline data, scientific findings and experience, condition assessments of gas pipelines are predicted in order to prioritize and plan maintenance and repair.

With the help of new technologies such as artificial intelligence and taking into account digitally available environmental data of the gas pipelines, potentials are opening up to (1) further increase the technical safety of gas pipelines, (2) additionally assess risks for humans and the environment and (3) forecast challenges due to hydrogen injection as well as (4) assess natural hazards due to climate change with the Integrity Management System.

As part of the digitization of operational and environmental data (INSPIRE), large volumes of data are available that are currently only inadequately evaluated for integrity management. The previous, empirical evaluation of data has reached its limits with the available data volumes.

dashboard PUBLICATIONS

Publications in development.

PROJECT LEAD:

STAFF | CONTACT:

person Tim Bastek, M.Sc.

email Send email

phone +49 721 6699 4703

Research focuses:

More Projects

SISProof – Safety Instrumented System Proof

Development of soft sensors for SIS monitoring and evaluation of limiting factors.

sRMC – Safety related Remote Process Monitoring & Control

Applying AI in acoustic-based sensor systems for gas leakage detection

ZEBrA – Zero-Emission Breathing Application for Storage Tanks

Development of an emission-free storage tank with construction and testing of a prototype.

Cover photo source "Tube Geometry", RiIM project: Harald Hoyer from Schwerin, Germany, CC BY-SA 2.0, via Wikimedia Commons

Cover photo source "Winstainforth", SafeDDT project, CC BY-SA 3.0, via Wikimedia Commons