Intelligent safeguarding of chemical reactors with adaptive safety devices.

dashboard Objectives

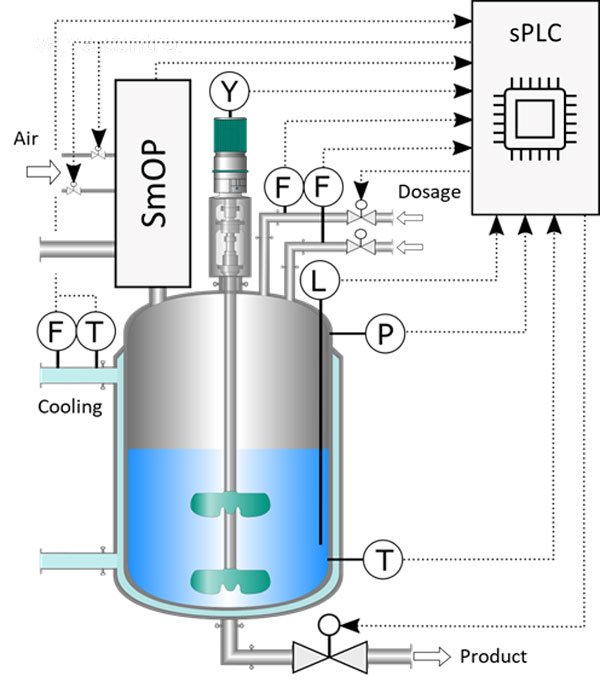

The goal of this research project is the development of an adaptive safety device, a “SmOP – Smart Overpressure Protection Device”, which adapts to the changing requirements of the operation and ensures its safety. The SmOP should be adaptable in set pressure and relief cross-section during the process and thus offer the greatest possible flexibility. The SmOP distinguishes between two operating modes: A zero-emission mode without pressure relief and a smart-relief mode with process-adaptive pressure relief. Faster reaction modes due to higher operating pressures are made possible, unstable valve behaviour (valve flutter) can be avoided, optimal discharge conditions for downstream system components can be realised and two-phase discharge can be prevented.

Smart safety devices – fiction so far, reality in the future! Smart safety devices can significantly increase the flexibility and productivity of multipurpose plants.

Figure: Smart Overpressure Protection Device in the system diagram.

dashboard MILESTONES

New method for online response tracking

Risk assessment based on the current hazard potential

Zero-emission / smart-relief mode for the protection of reactors

Application for various reaction types in the chem. Industry

dashboard Overview

Reactor simulation

Protection model

Online valve sizing

Safety-oriented programming

Miniplant experiments

dashboard Motivation

Mechanical safety devices such as safety valves and bursting discs provide sufficient protection against impermissible pressures even if a PCT control unit fails as a (component) tested fitting, which is why they are widely used in industry. If protection is provided by PCE safety devices alone, the filling level or concentration of the components must sometimes be greatly reduced, which is why the use of an additional mechanical safety device is recommended.

However, mechanical safety devices are specifically adapted in design to a particular process and reaction. Batch (BR) or semi-batch reactors (SBR) in particular, with constantly changing recipes and the associated changing safety requirements, present plant operators with enormous operational problems. Static relief cross-sections and set pressures also limit the productivity of the reactors – economic potential remains untapped. In an age in which 3D plant tours are possible, innovation is thus also needed in the safeguarding of chemical reactors. A Smart Overpressure Protection Device.

ashboard PUBLICATIONS

Schmidt, C., Schmidt, J. and Denecke, J.:

Smart overpressure protection devices to protect chemical reactors against exothermal runaway reactions. J. Loss Prev. Process Ind., vol. 82, 2023.

DOI: 10.1016/j.jlp.2023.104996.

Schmidt, C., Biernath, J., Schmidt, J., Denecke, J.:

Protection of Chemical Reactors Against Exothermal Runaway Reactions with Smart Overpressure Protection Devices. CHEMICAL ENGINEERING TRANSACTIONS VOL. 90, 2022, DOI: 10.3303/CET2290083.

Biernath, J., Schmidt, C., Schmidt, J., Denecke, J.:

Model-based zero emission safety concept for reactors with exothermal reactions for chemical plants. J. Loss Prev. Process Ind. 72, 2021, 104494.

DOI: 10.1016/j.jlp.2021.104494.

PROJEKT LEAD:

STAFF | CONTACT:

person Carsten Schmidt, M.Sc.

email Send email

phone +49 721 6699 4719

FOCUS AREAS:

More projects

EuroValve – European Program on Evaluation of Safety Valve Stability

Development of a new safety criterion for safety valves.

sRMC – Safety related Remote Process Monitoring & Control

Applying AI in acoustic-based sensor systems for gas leakage detection

RiIM – Risk-based Pipeline Integrity Management

Developing an AI-powered, risk-based pipeline integrity management system.

Cover photo source "Tube Geometry", RiIM project: Harald Hoyer from Schwerin, Germany, CC BY-SA 2.0, via Wikimedia Commons

Cover photo source "Winstainforth", SafeDDT project, CC BY-SA 3.0, via Wikimedia Commons